Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet-Dry Cutting Range: SIMA Diamant

Materials: Concrete, Granite, Brick. Diameter: 300 mm Laser welded segment.

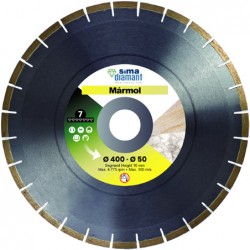

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Marble, Sandstone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Granite, Silestone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Stone. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Gres, Ceramics, Porcelain, Marble, Dekton. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: Abrasive, Refractorys. Diameter: 300 mm Laser welded segment.

Diamond Blade for Wet Cutting Range: SIMA Diamant

Materials: General Building Materials, Concrete. Diameter: 300 mm Laser welded segment.

Diamond Blade for Dry-Wet Cutting Range: SIMA Diamant

Materials: Green Concrete, Asphalt. Diameter: 300 mm Laser welded segment.

Diamond Blade for Dry-Wet Cutting Range: SIMA Diamant

Materials: Green Concrete, Asphalt. Diameter: 300 mm Laser welded segment.

Diamond Blade for Dry Cutting Range: SIMA Diamant

Materials: Concrete, Asphalt. Diameter: 300 mm Laser welded segment.

Diamond Blade for Dry Cutting Range: SIMA Diamant

Materials: Forged Iron, Steel, Concrete Blocks, Sandwich, PVC. Diameter: 300 mm Laser welded segment.

If your project involves working with machines such as a table saw or a petrol saw, the universal 300 mm diamond saw blades are your best ally. The 300 diamond blades is your must-have for cutting building materials. Use it with your power saw, floor saw or grinder to cut tile, concrete, bricks, asphalt or any kind of block.

Thanks to the diamond particles attached to the edges of the blade and kept in place by the metal bond, the diamond blade will offer accurate and clean cuts, preventing your working materials from chipping or cracking. A diamond blade does not actually cut, but grinds.

The synthetic diamonds are exposed, while it is still sharp, and grind the material. After working with your diamond blade for several hours, it will start to deteriorate, so it is important to keep an eye on the diamonds and dress the blade to ensure that it is still sharp and working properly.

Besides, we highly recommend wet cutting when possible, because if the diamond blade overheats, it deteriorates much faster. If you need to work near an electrical power source or using electrical tools, dry cutting might be preferred in terms of safety. If this is your case, remember to take pauses between passes while cutting so the blade won’t be too damaged. Moreover, you must wear your protective gear, such as gloves, glasses and a respirator mask, because depending on your materials particles might fly out or it could create a cloud of dust.